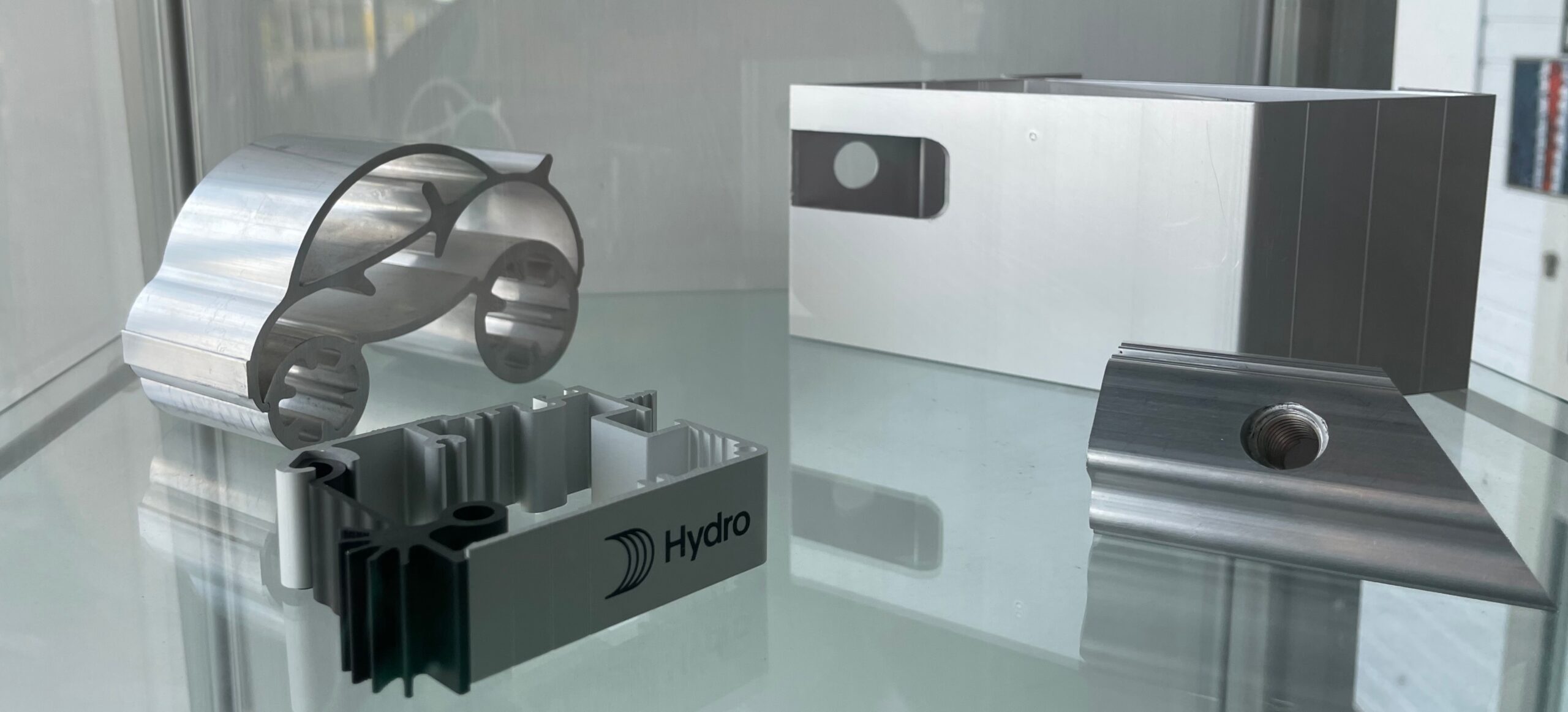

Case study: Metal fabrication, assembly and finishing

Partnership working delivers results for Hydro

Hydro is an international aluminium Group with strong sustainability ethos, and the ambition and action plan to achieve net zero by 2050. Working across 40 countries, it employs 31,000 people.

One of its businesses is Hydro Extrusions which offers aluminium fabrication and assembly, machining, coded mig and tig welding and anodizing. Also, Hydro Components offers an integrated in-house fabrication and surface finishing for the automotive industry. Customers include Aston Martin, Jaguar Land Rover and Rolls Royce.

“We’re already cut costs by £30,000 and we’re cutting carbon”

With the aim of improving operational effectiveness, reducing cost and carbon, across multiple manufacturing sites in the UK, Hydro is seeing the impact of implementing bespoke waste handling equipment from Enviroquip combined with a total waste management service from Forward Waste.

Market Sector: manufacturing

Locations: Caerphilly, Gloucestershire, and Derbyshire

“When I think of Enviroquip I think, professional, friendly, and honest. It’s very much a partnership…. There’s less waste collections, the equipment is in good condition, the yard is cleaner. Haulage is reduced, so less fumes, so less carbon…Costs drove us, and we’re gaining environmental benefits. ”

Mike Vernall, Health, Safety and Environmental Manager Hydro Extrusions

Customer Benefits

Cost reduction

Environmental best practice

Carbon reduction

Customer challenge

Across sites, the customer’s objectives were to reduce waste management cost, improve operational efficiency, and reduce carbon whilst managing multi-site consolidation and an anticipated 40% increase in general waste production.

Waste streams to manage:

- general waste

- wood

- cardboard

- metal

- plastic film

- non-hazardous filter cake

- hazardous waste

Our approach

An integrated waste handling solution which combines bespoke equipment and waste management services was designed to address Hydro’s business objectives, its unique waste problems, and site conditions.

Enviroquip waste handling equipment solutions:

- vertical mill balers

- static compactors with bin lifters

- self-tipping skips

- custom built containers

- colour-coded wheelie bins

- bespoke weather protection structures

- equipment service contracts

Our customer impact

- £30,000 saved over first six months

- Zero to landfill

- Carbon reduction

- Improved waste segregation

- Significantly reduced vehicle movements

- Improved team Health & Safety

- Reduced operational risk

- Improved team morale

- Reliable, timely waste collections services

- Significantly fewer equipment issues

- Improved quality of dry waste increasing rebate values

- Responsive, reliable service